Sheeting line

How to create the sheet dough and bring it to the desired thickness

Sheeting line allows to create a dough sheet of the thickness of approx. 10 mm, and, through following steps, to bring it to the desired thickness. The biscuit will be ready to be cut/printed as you prefer

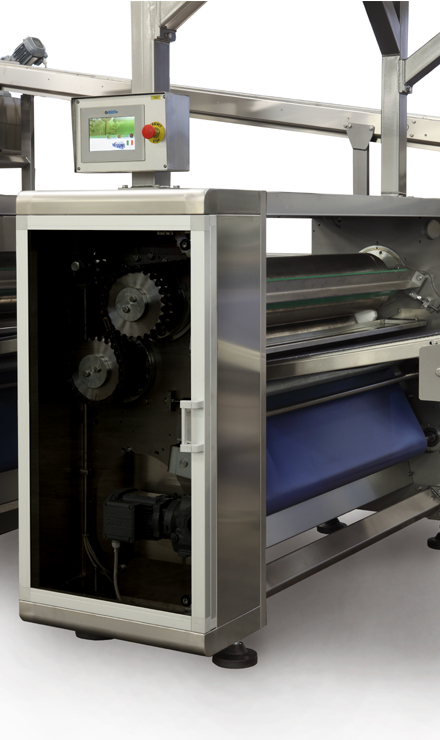

The line starts from a forming station composed by 3 (or 4) cylinders for the creation of the dough sheet: an hopper receives the dough and a continuous sheet of approx. 10 mm is created when the dough passes between the cylinders. A conveyor belt brings the dough to the following sheeting station

Sheeting lamination is composed by two smooth cylinders; the dough, passing through the (adjustable) opening between the two cylinders, gets thinner. The reduced sheet can then be transferred to a following sheeting station, to get even thinner, to a machine for cut and print or to a laminator, where it can be layered over other sheets

Three rolls sheeting unit (forming unit) Two rolls sheeting unit

The number of sheeting stations is determined by the length of the oven and by the feed speed of the dough sheet

The rotation speed of rollers and the feed speed of the conveyor belts are adjustable from the touch screen panel, and can easily be saved

It’s possible to adjust the stations’ speed or enable the “a cascade” regulation: in this way, when you set a station speed, all the prevoius stations will adjust automatically their speed in order to mantain the sheet intact and to avoid tearing and accumulation;

A photocell at the entrance of every stations check the sheet thickness and corrects the previous stations speed

Sheeteing should be also in vertical, in order to save space in your factory