3 colors Extruder 3EX 600

Create unique cookies with maximum precision and flexibility

The new 3EX 600 extruder machine is the ideal solution for those looking for maximum quality and versatility in the production of filled biscuits. Thanks to its advanced technology and sturdy construction, 3EX allows you to create infinite combinations of colors and shapes, satisfying even the most demanding palates.

• Perfect wire cutting: The (optional) wire cutting unit guarantees precise separation of the biscuits, without burrs and with an impeccable appearance.

• Complete automation: The automatic trays loader, extrusion pumps and cutting unit are managed by an intuitive touch screen panel, for simple and precise operation.

• Hygiene and safety: Made entirely of materials suitable for contatact with food, 3EX is easy to clean and sanitize. Numerous safety protections ensure a safe working environment for operators.

• Customization: Thanks to the numerous options available, you can configure your 3EX according to your specific production needs.

Diaphragm shutter Wire cut

• Superior quality: The precision of extrusion and cutting guarantees a high quality finished product, with a uniform and inviting appearance.

• Flexibility: Thanks to the possibility of creating infinite combinations of colors and shapes, you can satisfy the demands of an increasingly demanding market.

Main technical features

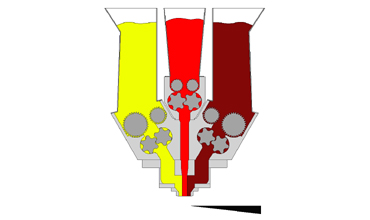

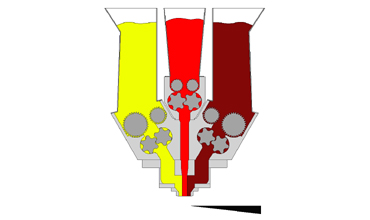

• 3 colors, infinite possibilities: Simultaneous extrusion of 3 different doughs to create filled biscuits with a soft center and a crunchy shell.• Perfect wire cutting: The (optional) wire cutting unit guarantees precise separation of the biscuits, without burrs and with an impeccable appearance.

• Complete automation: The automatic trays loader, extrusion pumps and cutting unit are managed by an intuitive touch screen panel, for simple and precise operation.

• Hygiene and safety: Made entirely of materials suitable for contatact with food, 3EX is easy to clean and sanitize. Numerous safety protections ensure a safe working environment for operators.

• Customization: Thanks to the numerous options available, you can configure your 3EX according to your specific production needs.

| Code | Dimension trays [mm] |

Installed power [kW] |

Dimensions packaging (approx) [mm] |

Gross weight [kg] |

Capaciy dough hopper [liters] | Capacity filling hopper [liters] | MAX closings / minute | MAX cuts / minute |

MAX hourly production [pieces / h] |

| 3EX 600 | W=600 L=400-800 |

6 | 2750x1600x H2000 |

1.000 | 25 | 20 | 70 | 70 | 29.400 |

- Aluminum and stainless steel AISI 304 main frame equipped with 4 pivoting wheels with brake for easy moving

- Charger for trays (max. 15) , withdrawal from the bottom through pusher chain. Chain moved by gear motor controlled by inverter group

- 3 dough extrusion pumps, each pump consisting of: hopper in stainless steel AISI 304, pair of feeding grooved rollers lobe pumps with separate chambers

- Movement transmission group made by gear motor controlled by inverter group and transmission box

- Conveyor group for the dough to the mold (filler-block) in aluminum alloy with anti-wear and anti-corrosion treatment

- Forming mould made of aluminum plate with anti-wear and anti-corrosion treatment, for coupling with filler block, intermediate plates in high-resistance food grade plastic material, inner nozzles and external extrusion cups

- Diaphragm closing mould made by anticorodal aluminum support plate, closing diaphragms in food grade plastic material, handling through pneumatic pistons

- Mechanic device to rotate extrusion nozzle (twist), moved by gear motor lead by inverter group (continuous rotation)

- Color touch screen panel on the machine side for the management of all the functions of the machine, saving and modifying receipts, alarms management

- TELESERVICE module for remote assistence

One head, three different working systems

Diaphragm shutter Wire cut

Guillotine (fig-bar)

Advantages

• Increased productivity: Process automation and ease of use reduce production times and increase efficiency.• Superior quality: The precision of extrusion and cutting guarantees a high quality finished product, with a uniform and inviting appearance.

• Flexibility: Thanks to the possibility of creating infinite combinations of colors and shapes, you can satisfy the demands of an increasingly demanding market.